One of the most commonly used equipment to lift heavy loads on construction and manufacturing sites are the cranes. However, this often used equipment comes with some serious potential hazards, which is why it is extremely important that only the experts should handle them. The experts of the EOT crane Manufacturer in Gujarat should always take care of the safety of the labours who are involved in the process. Any company before working with the crane company should find out about the statistics and work experience of the company. As the top EOT crane Manufacturer in India, Hoistandcrane can help you provide safety at all stages of operation.Did you know that the Bureau of Labor Statistics reported 297 deaths within 2011 to 2017 involving cranes? So, it is absolutely essential to have proper crane safety at all stages of operation, which starts right from the moment of travel, setup, rigging and lifting.

Here are the safety tips that if followed can help prevent any such accidents

Get the right crane

Choosing the right crane is the foremost step in ensuring safe crane operation. Generally, the fixed cranes are used in industrial settings or in places which need complex or tall construction projects. However, the mobile cranes are available in a number of places because of its versatility such as – Carry deck crane, Crawler crane, Rough-terrain crane and All-terrain crane. Whatever is the type of crane being used, the safety measures vary and only an experienced operator and supervisor can get it done rightly.

Working with qualified personnel

Speaking about safe operation of cranes will be incomplete if there are no words about the importance of trained personnel. It is paramount to have persons who can set up, rig, signal and operate the equipment correctly. The Occupational Safety and Health Administration (OSHA) has laid down regulations which states how only the trained, certified and evaluated individuals to operators shall be allowed on the job sites.

Have a thorough read of the operator manuals

Even when qualified personnel are taking care of the crane operation, it’s important to remember that there can be some difference in the final manufacture of these machines varying amongst the companies. They can have unique controls, brake, failsafe devices and other features. Anyone operating the cranes should have most definitely have a thorough read of the manual of the specific crane.

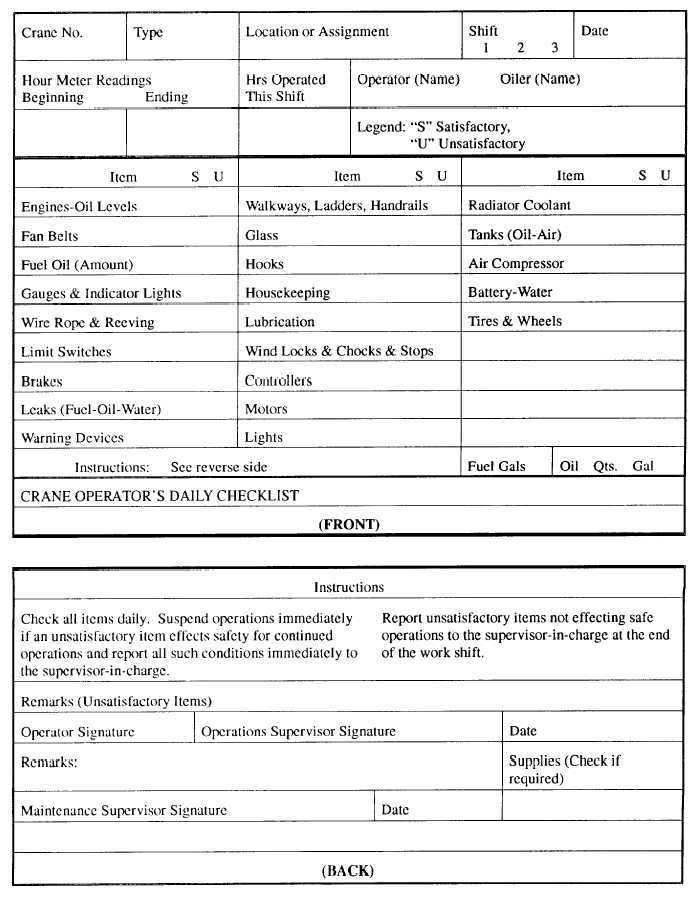

Daily Operator Checks

It is mandatory to have daily inspection prior to operation which must include the parts such as pre-start checks, engine start-up checks and safety system checks. Also, there must be proper inspection of the hydraulic system to avoid any issues on the worksite.

Clear all hindrance on the way

Before the crane starts moving, the entire path should be cleared of all obstacles. It is not possible to remove things such as power lines or other permanent features but the crane operator should keep a safe distance at all times. One of the rules is to maintain at least 10 feet distance from power grids of 50,000 volts. This is why, you must have a trained signal person to alert the crane operator.

Stabilize Before Rigging and rig correctly

Mobile cranes need stabilizing features to stop the equipment from tipping over, specially when in motion. Make sure to follow manufacturer guidelines and never place outriggers over unsteady ground. Proper rigging of loads will stop from any potential accident.

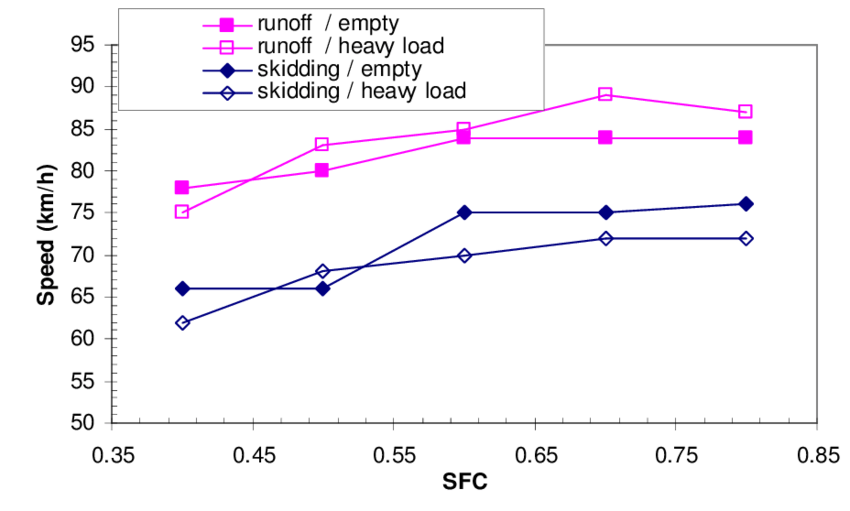

Load Radius and Load Limits

Load radius shows states that the further the load is from the centre of the crane, the less it can carry and is dependent on the angle of the boom. Similarly, make sure to follow the load moment indicators which shows if you are going up the rated capacity.Load charts explain how much a crane can lift in different situations.

Manage complex lifts

Complex lifts are those which involve loads more than 80 percent of crane capacity or is above 50 percent of crane capacity. It’s vital that there is complex lift plan in place which can provide signals in case of any risk for tip-overs or equipment failure.