Modern industrial machinery has made industrial processes faster. The machines not only save time but efforts as well. And that’s the reason, the electrically and mechanically powered tools are getting immense popularity. Crane is also one such device which has made load handling and moving a lot faster, safer, and easier. According to crane manufacturers in Ahmedabad , the cranes need to be maintained well to ensure safety. Apart from maintenance, several other factors contribute to the proper working of the device. Let’s see what it takes to operate and maintain a crane the right way.

Operating It Right

Operating the crane the right way starts with hiring someone who has the knowledge and experience to operate such a tool. The person must have gone through the required training before taking up the job.

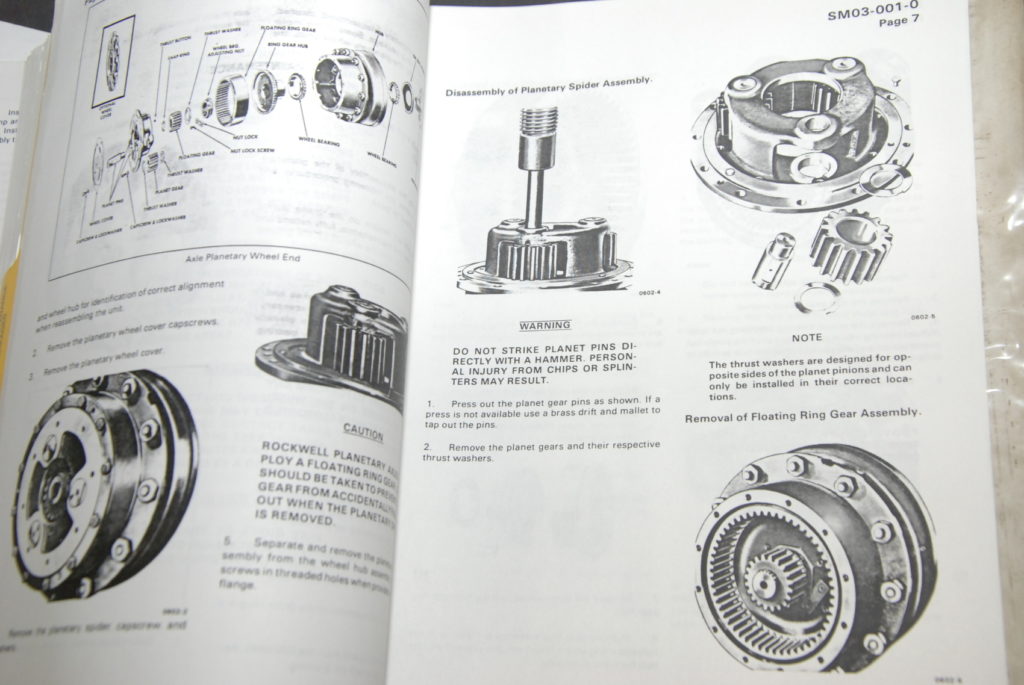

Maintenance Manual

- Make sure to receive your maintenance manual from the seller so that you can take care of the machine well.

- Do not try to repair anything yourself. Have at least two technicians by your side while carrying out any such operation.

- Make sure to turn off the power supply before starting with the maintenance procedure.

- The technician or maintenance professional on top of the crane must take the tool kit along. Not only will it make things easier, but will prevent accidents as well.

- Any part or panel opened for repair must be sealed properly before starting the crane again.

Preventive Maintenance

You need to take care of the crane well so that you don’t have to get it repaired. Preventing maintenance includes checking everything on a daily, weekly or monthly basis. Regular use can cause wear and tear that might get unnoticed if you don’t inspect the device well every day.

- Maintain a daily, weekly, or monthly schedule for each part of the crane for maintenance.

- Keep the tool kit ready and replacement parts ready.

- Ensure easy access to every part of the crane to make the process smooth.

- Bring a safe ladder to climb the highest point safely.

- Maintain a report of your periodic checkup. It will make tracking issues easier.

Regular Checklist

- A few things you must check daily are:

- All the control operations are set right.

- Oiling and greasing is done for required parts.

- The rope is free from any cuts or kinks.

- The push-button cable is not holding the weight of the push button station. The job is intended to be done by suspended rope.

- The contacts are free from any carbon accumulation

What To Do?

- Hire a skilled operator who knows all the operations well.

- The operator should understand and know all the hand signals and other safety instructions.

- Must call a skilled professional whenever some repair is required instead of experimenting.

- Must be attentive and quick decision-maker based on common sense to handle the situation when something goes wrong.

What Not To Do?

- The suspended load is extremely dangerous and that’s why no one should walk under it. No matter what’s the matter, no one should pass beneath the load. Even if there are some repair issues, the worker needs to be at a distance from the load for safety reasons.

- If there is any electrical, mechanical, or physical issue with the hoist, do not try to start it before repair.

- You can’t lengthen the wire rope yourself, don’t try it.

- Keep the welding electrodes away from the wire rope to avoid any damage.

- Don’t use a load limiting device to measure the load. The device is named as per its purpose.

Taking care of the crane and its operation not only expands the lifetime of cranes but also improves safety.